Introduction

Older styles of electricity cables contain oil to improve their insulation properties and to enhance cooling. Occasionally, from time to time, these older cables leak when equipment is damaged, seals deteriorate or as a result of changing ground conditions. When this happens we take steps to ensure that any damage to the environment is minimised through the removal of contaminated ground and that the leak is fixed as quickly as possible. We’re also putting in place measures to help reduce the overall number of leaks that we have across our network.

Oil leakage

The risks associated with operating fluid filled cables (FFC) and related assets can be reputational, regulatory and financial. The primary risk is associated with the leakage of insulation oil into the environment causing pollution. Leaks typically occur as the cable sheath deteriorates with age, at joint failures or as a result of third-party damage.

To minimise environmental damage we aim to ensure that:

- Fluid levels in all our cables are monitored remotely, the loss of pressure triggering an alarm in our Control Centres. This enables us to react quickly to any leak event.

- Leaks are located quickly using perfluorocarbon tracer (PFT) and repaired.

- Cables with a history of high leak rates are selected for replacement.

Additional mitigation may range from visual inspection or PFT tracing, to spot repair, sectional drain and seal or the full extraction of the cable.

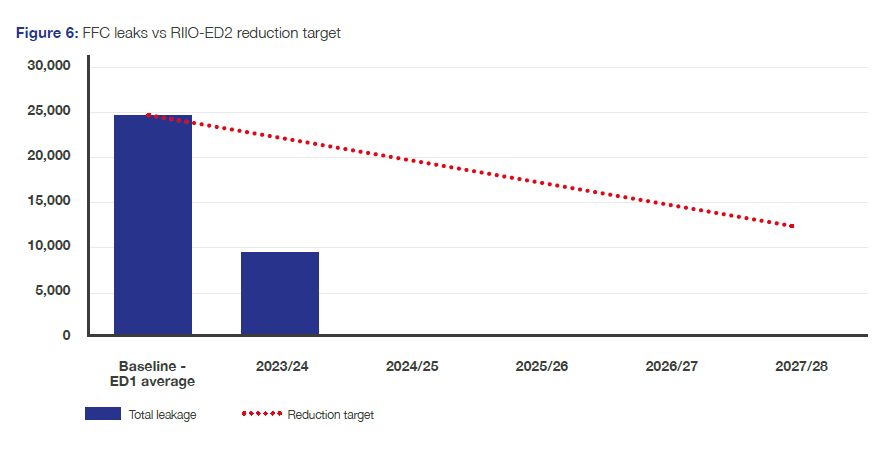

All leak rates are recorded and a database of leak and cable information is held centrally. Monthly reports of fluid filled cable leaks are submitted to both the Environment Agency and Natural Resources Wales. The volume of oil leaked from fluid filled cabled during 2023/24 is significantly less than the baseline period (3-year average of performance for 2019/20 to 2021/22) and we have therefore achieved NGED targets for the first year of RIIO-ED2 as shown below.